A version of this blog originally appeared in Food Industry Executive.

It’s the news that every food and beverage (F&B) manufacturer dreads - people are getting sick after consuming your product.

Employees scramble to shut down production lines and investigate the source. Leaders are demanding to understand the scale of the issue, faster than confident answers can be provided. Should we institute a recall? Of all the teams mobilized during these kinds of events, the news hits hardest for food safety and quality. Wondering what they missed. Could this have been avoided?

In the F&B industry, food safety and quality are imperatives. They are the bedrock of consumer and public trust. They take years of consistent performance to earn, and can be lost in an instant.

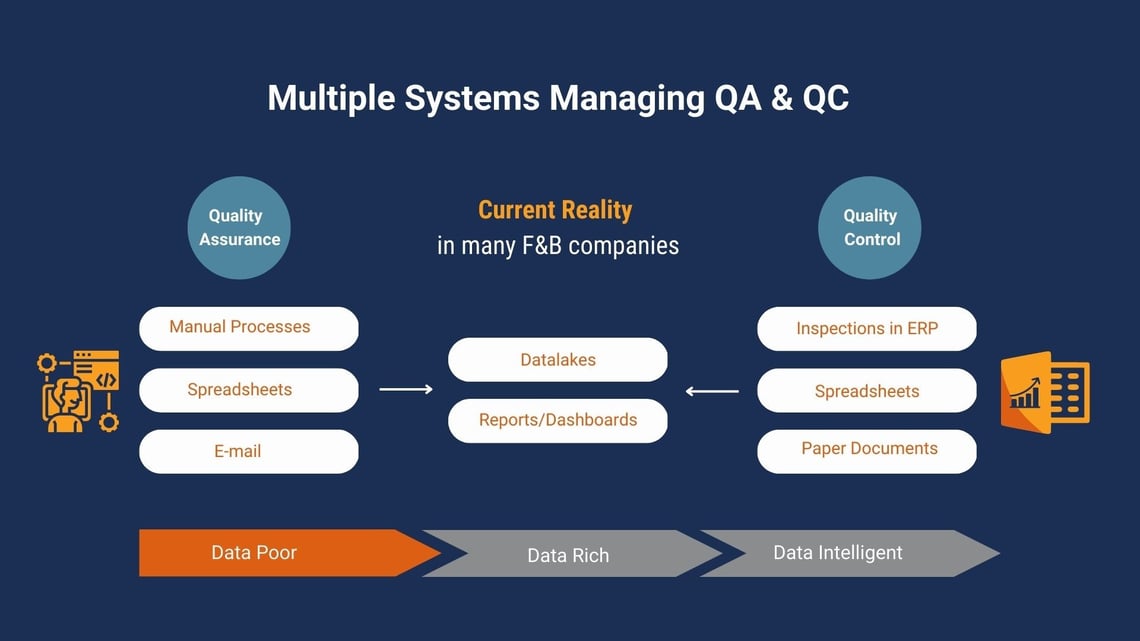

Until recently, most teams responsible for managing these critical processes were using yesterday’s technology - disparate spreadsheets, email, outdated on-premise software, even paper files.

Leading F&B companies are now modernizing food safety and quality management with unified, cloud-based solutions that are purpose-built to allow them to evolve their approach from reactive to preventative, and ultimately to predictive. These initiatives promise to enable more streamlined operations and better business outcomes, as well as avert brand reputation damage and consumer suffering.

Unnecessary Risk: The Cost of Reactive Food Safety and Quality Management

F&B industry leaders emphasize the paramount importance of food safety and quality. Despite this, many companies have yet to invest in modernizing their management systems, posing avoidable risks for both businesses and consumers. Within F&B manufacturing, disjointed legacy systems hinder connectivity and rely heavily on manual input, leading to poor data quality and limited access. This reactive approach often results in identifying safety issues only after harm has occurred.

Following the business operations disruptions of the past few years, some forward-thinking food safety and quality leaders have recognized how untenable these outdated systems are for such critical business processes. Additionally, the workforce generation that set up and is most comfortable working in these systems is retiring. Meanwhile, new hires are increasingly vocal that these disjointed processes and disparate systems are inconsistent with stated organizational values and don’t set team members up for success.

The most common food safety and quality management systems at companies today make it nearly impossible to comply with leadership requests to make data-driven decisions, proactively identify trends, or provide visibility. To drive better business outcomes and stay ahead of their competition, it’s past time to modernize and unify.

“I’m really looking at moving from a way of managing food safety that I still see as being very static to a completely dynamic one,” said Olivier Mignot, Vice President of Global Quality Management at Nestlé. “We evolve our monitoring plan maybe once a year. And in the meantime, a lot of things are happening: change of suppliers, response to loss, sustainable sourcing, change of raw materials, climate changes, impact of seasonal variation to the quality of the crops that are used for the raw material.”

How Unified Systems Set the Foundation for Predictive Food Safety and Quality

In my team’s work with leaders in the F&B industry, we’ve seen many recognize that technology solutions and digitization are required to move from reactive food safety and quality management to a more proactive and ultimately predictive approach. Achieving this evolution requires many elements, and at its foundation is having the right data.

If you’re like most of your peer companies, your food safety and quality data is spread across multiple, disparate systems, and the context that brings meaning to that data is not harmonized.

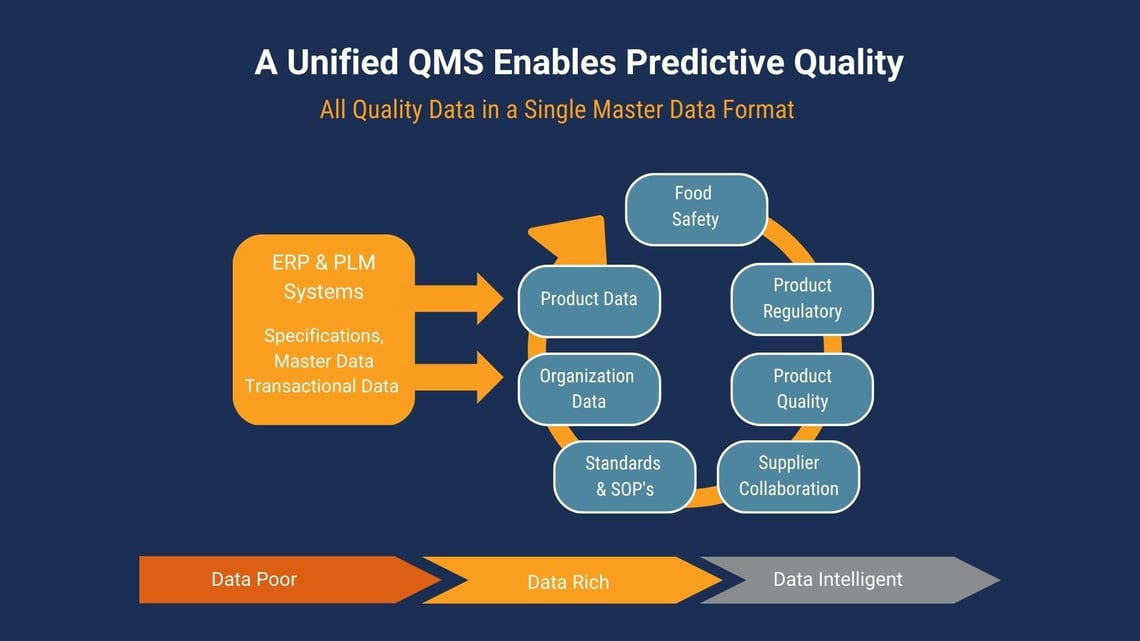

Without bringing key food safety and quality documents, data, and processes into a single context on a unified platform, it’s impossible to deploy the modeling necessary to achieve insight-driven predictive quality.

For example, when I worked in corporate quality management at a top global CPG company, my team asked ourselves if we could look upstream in our supply chain to identify risks that would increase the likelihood of a marketplace incident that would rise to the level of a product recall.

We looked at supplier non-conformances and non-conformances in manufacturing environments as “early warning” signals to indicate that facilities were at increased risk for a marketplace incident should these non-conformances go unnoticed in the future. After tremendous effort pulling together data from many sources and systems, we identified trends and patterns for early risk signals and proved the principle - events upstream in the manufacturing chain could identify increased risks of non-conformances downstream, and perhaps forewarn product recall.

But in a “data poor” environment, automation was not feasible due the misalignment of the data. The prospect of marshaling the resources necessary to replicate this type of analysis, or ongoing monitoring of these indicators, was simply infeasible. This predictive, risk-based approach could only be implemented if and when all data was captured in the same systematic way, embedded in the same master data, across the enterprise. Such a “data rich” environment would then enable many more indicators to be included and used as parameters and apply AI/ML to model the risk of a recall.

“We really want to be able to think differently, to be able to bring all this data together,” said Deann Akins-Lewenthal, Senior Director of Global Food Safety at Mondelēz International, “whether it’s internal manufacturing data, external manufacturers, or suppliers, and start looking at what are those leading indicators that might say something’s changed.”

The Importance of Establishing End-to-End Visibility of Quality Information

Beyond data quality, investing in technology to unify quality assurance and quality control enables end-to-end visibility on quality information. Unifying these siloed processes, management systems and data sources frees up valuable employee time for more strategic tasks, streamlines operations, and ultimately drives better business outcomes.

In a unified system as illustrated in the diagram above, users can securely perform all their procedures, and associated data is captured in a consistent, structured environment. This can also be integrated with related sources of truth like specification and ERP systems. Additionally, data from external stakeholders like co-manufactures and suppliers can be securely stored and accessed for enhanced collaboration, traceability, and visibility.

You may be wondering about the value of managing quality and food safety in a single solution. This is a reflection of the intertwined nature of joint processes, while still preserving the differentiation of quality and food safety events and enabling rapid action based on incident severity.

Establishing a unified food safety and quality management system like this is the critical foundational step for transforming from a data poor to a data rich environment, laying a strong foundation to bring about predictive quality and food safety.

Single Source of Truth Unlocks Collaboration, Insights

If this vision inspires you, prepare yourself for the final stage in the progression from reactive to preventative to predictive - becoming data intelligent and benefiting from your data becoming the new “appreciating asset”.

Such a unified system is set up to automatically capture and analyze structured data from a variety of sources. This enables organizations to finally “connect the dots” to identify risks and trends in real-time, offer transparency to all relevant stakeholders, and facilitate proactive steps to head off future issues. Over time, insights from the ever-increasing data pool become increasingly confident and more valuable to the organization. Insights can be turned into learnings that help sharpen quality assurance and quality control processes, leading to the continuous improvement we all strive for.

What could this look like in practice? Let’s take an example present in any F&B company - processing certificates of analysis (CoAs) from suppliers. Today, this is usually a labor intensive process involving manual verification and data transcription, and then the paper (and its data) are stored in binders. The amount of effort an enterprise-sized organization spend on this manual process is significant, in the range of ~75 FTE per million CoAs.

In another application, we are partnering with a global top three F&B organization to digitally transform its HACCP management. The spreadsheets this company had been using for HACCP management were recognized as too labor intensive to maintain and impossible to standardize across the company. Now their team is working with us to shift to a cloud-based system that structures all of the pertinent data, share expert knowledge with their factories, and allow the company to better compare how HACCP is implemented across its factories. Additionally, this company is working with us to radically simplify the way factory users interact with the information captured in the HACCP system.

Towards Predictive Food Safety & Quality Management

Investing in a modern solution to unify food safety and quality management is helping F&B market leaders shift from reactive to preventive to predictive, and driving cycles of continuous learning and improvement.

Are you ready to explore how such a solution could enable more streamlined operations and better business outcomes in your organization, as well as avert brand reputation damage and consumer suffering?

We encourage you to contact us to set up a brief exploratory conversation and hear how F&B market leaders are using technology to make progress towards this vision.

SHARE