Visit our Quality Solution Page to learn more about QualityOne.

In recent years, organizations have faced significant challenges impacting global supply chains, underscoring the critical role of quality management in consumer-centric industries.

While businesses strive for consistent quality, compliance, and continuous improvement, common pitfalls can still emerge. Effective quality management is essential not just for competitiveness and regulatory compliance, but also for factors like revenue, labor costs, and brand reputation, which have all been significantly impacted in recent times.

To prevent quality issues from escalating and maintain a competitive edge, proactive quality management is critical. If your company is facing quality challenges, you're certainly not alone. Let's explore seven common pitfalls and how to address them effectively.

7 Quality Management Issues

1. Leveraging Technology

While traditional methods like spreadsheets and paper trails were once the norm for quality management, the digital revolution has spurred advancements in efficiency.

However, many firms haven't kept pace, clinging to outdated practices. This manual approach is susceptible to errors and bottlenecks, hindering competitiveness in today's dynamic market. Modern technology offers a solution – robust quality management systems can streamline processes, improve accuracy, and empower businesses to thrive.

Related Post: 5 Best Practices for Securing the Right Cloud-Based Software to Achieve Your Digital Transformation

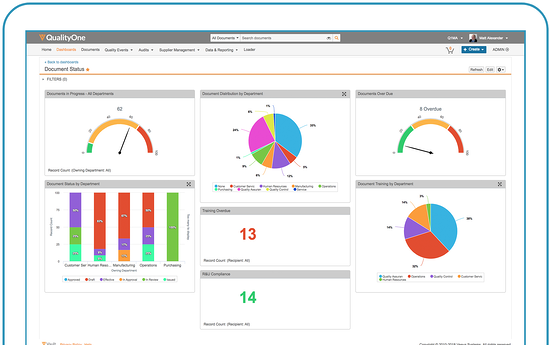

Modern Quality Management Software (QMS) empowers data-driven decision-making and continuous improvement. These cloud-based solutions streamline processes, automate tasks, and provide real-time insights for proactive quality control. Unlike legacy systems, QMS scales seamlessly with your organization, ensuring ongoing agility and strategic alignment.

2. Siloing Quality Management

The last recent years have underscored the need for a holistic approach to quality management. A siloed department solely responsible for quality hinders true organizational excellence. This structure fosters a culture where quality becomes the sole responsibility of a single team, neglecting the crucial contributions of frontline staff, managers, and suppliers.

According to a Forbes and ASQ survey of 1850+ executives, 20% of surveyed companies identified as siloed or struggling with their quality efforts. The same survey found that 84% believe quality issues, to some degree, are holding back their business’s ability to compete, and 85% say they have incurred some revenue loss due to ongoing, quality-related issues.

Modern quality management demands integration across the entire value chain, from raw materials to customer experience. Technology plays a vital role in this transformation, facilitating streamlined quality procedures, document management, and collaborative training across all departments and external partners. By fostering a culture of shared accountability and leveraging digital tools, organizations can achieve vigilant quality oversight at every stage, ensuring resilience in today's dynamic market landscape.

3. aligning Quality Management systems to business goals

In today's competitive landscape, quality management isn't just about compliance – it's a strategic driver for profitability and sustainability. Beyond the immediate disruptions of the past two years, strong quality practices directly impact revenue, brand equity, and productivity. Investing in employee training and fostering a culture of quality excellence empowers businesses to deliver consistent, high-quality products. Partnering with a quality modernization expert can help implement best practices, ensuring long-term success and a resilient brand reputation.

4. Covering highly Complex Supply Chains

Proactive management of your supplier network, encompassing qualification, training, and ongoing compliance, is essential. Today's globalized supply chains are far more complex than their localized predecessors, presenting unique quality challenges. Managing this vast network can be overwhelming without the proper tools. Spreadsheets and paper-based systems are simply inadequate. Unidentified quality issues can lead to costly product recalls, tarnishing your brand and placing the blame on your quality team for supplier errors.

Related Post: 4 Ways to Leverage Your Quality Management Processes During Unprecedented Supply Chain Disruption

Modern technology empowers proactive quality management. Robust Quality Management Systems (QMS) provide real-time visibility and transparency across your entire supply chain, enabling early detection of potential problems before they impact your brand. Invest in tech solutions to optimize your supply chain for seamless operations and ensure consistent product quality.

5. Staying Up to Date with Quality Management System Trends

The rapid pace of change in today's market demands agile businesses, but outgrowing your quality management system can be disastrous. Before launching a new product, ensure your quality processes are adaptable and aligned with evolving needs. Efficiency is paramount – new products must meet strict compliance, safety, and quality standards while hitting the market quickly. Agile quality checks are key to faster market entry and maintaining competitiveness.

Embrace technology to automate quality management processes. This empowers your business to adapt to market shifts, seize new opportunities swiftly, and minimize production issues, ensuring consistent quality for your customers.

6. moving from Reactive to proactive Quality Management

Businesses must stay agile to seize trends and new markets swiftly. However, outpacing your quality management system can lead to significant issues. Before launching a new product, ensure your quality processes are adaptable and aligned with evolving needs. Efficiency is key for businesses in a dynamic marketplace – new products must meet strict compliance, safety, and quality standards while hitting the market quickly. Agile quality checks are key to faster market entry and maintaining competitiveness.

Related Post: What is Quality Improvement? The Ultimate Guide

Discovering an effective quality management process tailored to your business is crucial. But many businesses overlook the importance of evaluating and refining their quality practices regularly. This negligence can lead to costly overcorrections when issues arise. The recent Boeing 737 Max crisis serves as a stark reminder of the consequences of neglecting proper quality checks during development. Just like the human body needs regular checkups to maintain optimal health, so too does your quality management system. Quality management is a dynamic process, not a static one.

7. Anticipating Quality Management Issues

Manufacturing thrives on quality. A robust quality management system isn't just about catching problems – it's a proactive shield for your entire operation. By fostering a culture of quality and embracing innovative technology, you empower your team to identify and address potential issues before they disrupt production.

Flexible and efficient quality management solutions, integrated with real-time data, provide continuous insights to anticipate problems and ensure smooth operations in today's dynamic landscape. This proactive approach not only elevates your brand reputation but also saves valuable time and resources.

Veeva Can Help You Solve Your QMS Challenges

Struggling with Quality Management? Explore Veeva QualityOne. It's user-friendly, cloud-based, and committed to streamlining operations for enhanced customer loyalty through quality.

Updated on April 26, 2024

SHARE